- 地址:

- 浙江省宁波市鄞州区银晨国际1号楼19楼

- 电话:

- 15336636830

- 产品详情

Product Description

Ningbo CNC OEM Machining Part

Aluminum is one of the most commonly utilized materials in CNC machining.

It has a good balance of strength, weight and finish.

It can be put through a large number of surface treatments such as Anodizing, Hard Anodizing, Bead Blasting, Chromate Conversion etc, in order to achieve the fit and finish you require.

Aluminum is easily machined, as it is fairly soft when compared to carbon steels.

The main classification:

Mechanical processing have manual processing and CNC machining two types. Manual processing is means machining various materials by mechanical workers manual milling machine, lathe, drilling machine and the sawing machine and other mechanical equipment. Manual processing is suitable for small batch production, simple parts. Numerical control machining (CNC) means the mechanical workers use numerical control equipment, the CNC equipment including CNC center, milling center, wire cutting equipment, thread cutting machine, etc. The vast majority of the machining shop machining the parts by numerical control machining technology. Through programming, coordinates the parts in the Cartesian coordinate system (X, Y, Z) into a programming language, the CNC controller of numerical control machine by identifying and explain programming language to control the axis of CNC machine tools, automatic removal of material, get the part according to the requirement and finish machining. CNC machining in a way that is straight artifacts, suitable for mass and complex shape parts.

Step of working out process regulations:

1) Calculating annual production program, determine the type of manufacture.

2) Analysis part drawing and the product assembly drawing.

3) Select blank.

4) Formulation process route.

5) Determine the machining allowance of each process, calculating the dimension and tolerance.

6) Identify the equipment used in each process and cutting tool, jig, measuring tools and auxiliary tools.

7) Determine the cutting dosage and man-hour quota.

8) Determine the main process of technical requirements and test methods.

9) Fill in the process documents.

The kinds of material of OEM CNC machined product:Aluminum, zinc alloy, steel alloy, copper;

The precision of the CNC machining OEM part: H6;

Smoothness of surface after OEM CNC Machining Part: Ra0.8;

Our company's OEM machined part production equipment and management system

CNC machining center: 8 sets;

CNC lathe machine: 6 Guangzhou Machines and 7 Shenyang Machines;

Work days of one week: From Monday to Saturday;

Shift work: 2 shift per day;

Working hours: From AM 8:00 to PM 5:00;

2D and 3D drawing Software: AutoCAD, UG, Pro/E, SolidWorks 2013;

QC control: New type NANO CMM, FPI M5000 desktop metal analyzer, Easson projector, Mechanical properties tester.

Aluminum OEM machined part equipment and QC control equipment

其他相关产品

查看更多>

PVC Electricians Tape Ningbo

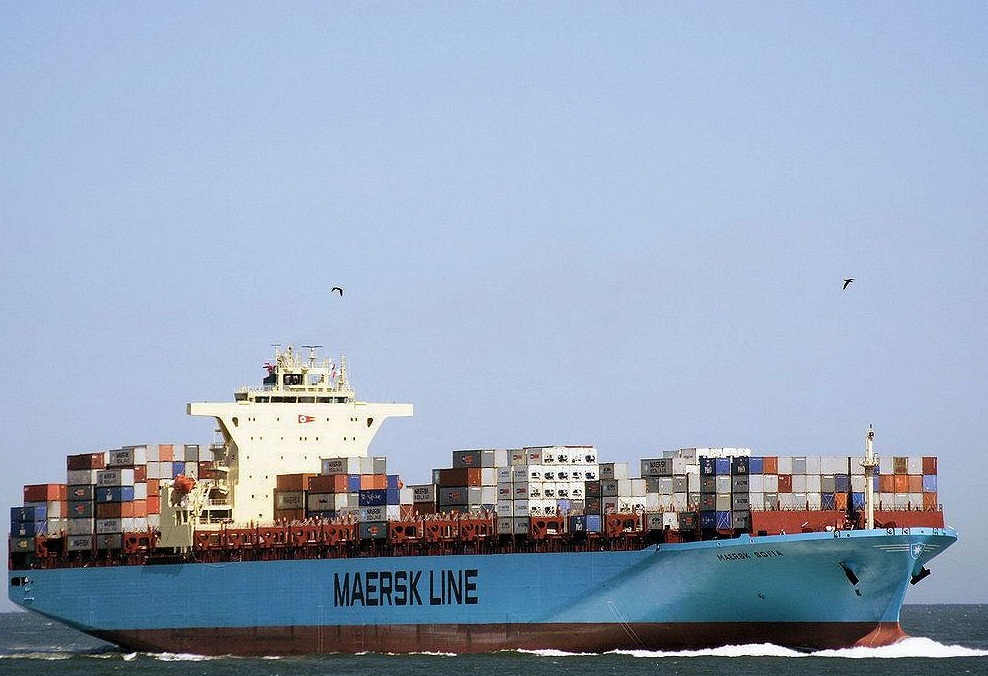

Latest Sea Freight From Ningbo Yiwu Shanghai Guangzhou Shenzhen HK to San Jose Guatemaka City Sea Freight

Ningbo factory cast aluminum A380

Ocean Sea Shipping From Ningbo Yiwu Shanghai Guangzhou Shenzhen to Hososhiima Imart Matsuyama Mizushima Japan Trustful Sea Freight Forwarder

ningbo die casting aluminum auto radiator with good quality